Most important is the plot which should be of adequate size for both present needs and future development. Since most fish processing plants are capable of processing high volumes of products foodborne outbreaks can potentially affect large sectors of the population.

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

To demonstrate the flexibility of facility design a prototype was developed at the University of Florida.

. Farm labor to process limited quantities of fish. Plant Identification News Symbols used for food plant design and layout 61-70 Lesson 11. The layout should be arranged so that raw material and finished produce are kept apart thus avoiding the possibility of cross-contamination.

Fish Processing Plants HACCP - 1 - INTRODUCTION There are a variety of potential hazards for most foods many of which can occur during the processing stage. Symbols used for food plant design and layout Lesson 10. Different processing areas and storage.

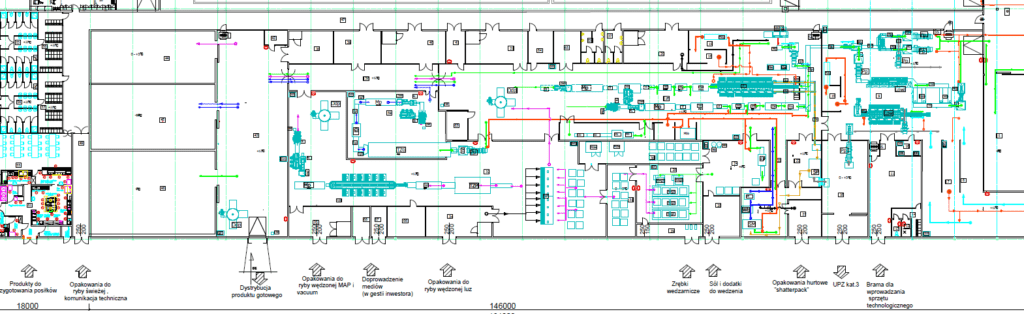

SAMPLE LAYOUT FOR A FISH PROCESSING PLANT. It discusses things you should think about and questions you should ask. Plant design Normally the plant design starts with a simple layout drawing.

Symbols used for food plant design and layout Lesson 10. Processing after a cleaning or washing operation should be kept apart from pre-cleaning processes. 61 Plant Location Buildings and Layout Before deciding plant location different factors should be analysed.

The simple reason is that every part inside the processing plant. Plant Layout 44-50 Lesson 8. Smaller fish processing plants are in common carp or trout objects near the f ishing farms offering processed production from their own resources production.

Processing and Marketing Aquaculture Products On. It takes experience and expertise to design and equip a fish plant. The plant should be close to public transport Access to electricity water and steam is essential.

Symbols used for food plant design and layout 61-70 Lesson 11. An example floor plan is shown in Figure 1. The additional area should be provided only if there is a requirement for.

Make sure you get advice from people who understand fish processing who understand Alaska construction and fish processing regulations and who understand the special conditions in building and operating processing plants in Alaska villages. A plant cannot. Introduction to plant design situations difference and considerations Lesson 2.

PDF PDF packaged in a food establishment or a food processing plant. With the urban areas there is need to establish fish factory plants in Kisumu. The size of that objects oscillates oscillates between 250 500 m2.

And design your layout. This is especially due to the decrease of on-board fishmeal and fish-oil. It focuses on small locally-owned fish processing operations in western Alaska but much of the handbook is relevant to any fish processing operation regardless of its location or size.

The layout should ensure that drainage is always away from the finished product and other clean areas. Food plant design process 21 Introduction The design process on all projects follows the same stages of development. It also covers Good manufacturing practices in Food Industry Case Study for.

PM2077pdf - Read File Online - Report Abuse. So the sizing of each process location is very important from the energy conservation point of view. A well designed and constructed system provides.

In order to make sustainable design of the fish and seafood processing equipment it is necessary to know and understand morphological properties of the fish resistance properties of the fish body formshape of the body and etc. To extract oil from the fish is the wet steam process. In addition to the land an average Rs.

Fish byproduct manufacturing Figure 9131-3 begins with cooking the fish at 100C lower for some species in a continuous cooker. PROJECT COMPONENTS Land and Building A plot of land of around 05 acre shall be required which would cost around Rs25 lakhs. 50 Lakhs are required for the development of land depending on the topography of land.

However the extent and detail of the activities behind each stage are different with every projectThere are a number of different industry formats for mapping the stages in the engineering process. This paper offers an approach that enables hygienic layout design of a food-processing plant that is particularly useful in production engineering and design for food processing companies that. Download full-text PDF Read full-text References 10 Abstract The success of any production system relies greatly on farm design and construction.

It takes experience and expertise to design and equip a fish plant. You will probably need advice. For these reasons remarks and guidance on plant design are set out below Shapton and Shapton 1991 Hayes 1985 EEC.

Their main products includes fresh gutted fish gutted steak fillet carcass in ice MAP or vacuum. Fish Processing Plants HACCP - 1 - INTRODUCTION There are a variety of potential hazards for most foods many of which can occur during the processing stage. Fish processing plant design and layout pdf.

The facility is designed to process. There also must be structured mechanisms established by local government to help recognize the needs of the fishing industry. 113 Research problem In this thesis I have investigated the potential of having a fish processing plant in Kisumu.

The area should be well enough to process the required quantity. This process coagulates the protein and ruptures the cell walls to release the water and oil. The on-farm processing facility utilized a 15 feet x 15 feet area of an existing metal building.

This handbook gives advice about planning a fish processing plant in an Alaska village. The only process used in the U. At seafood processing plants achieving the highest quality water standards is paramount again to prevent contamination and to attain proper moisture to keep fish products in the proper conditions.

Layout can be described as location of different deptts and arrangement of machinery in a deptt. The general process flow chart of fish canning is given below. The dimensions and arrangement of facilities in the current plant layout was used as a guide when designing the new plant layout.

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

Establishments And Production Demands For Freshwater Fish Processing

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

Fish Processing Plants Design Equipment Technological And Construction Projects

Pdf Modelling And Simulation Of A Fish Processing Factory Ship Semantic Scholar

0 comments

Post a Comment